McSurgical: Using the fast-food giant’s irrefutable recipe for efficiency to revolutionize operating theater fit-outs

From Big Mac to Big Impact; McDonald's kitchens are infamous for designs which have pioneered efficiency. So why don’t we use more of those principles in medical settings to maximize efficiency and we

A Netflix recommendation, if you've not seen it: 'The Founder'. It details the story of how McDonalds was founded and scaled to become to behemoth that it is today.

It's a great film about overcoming business challenges and spotting market gaps.

McDonalds really won over their competition for two reasons; the first is standardization of their products - everyone who ordered knew it would always look, taste and cost the same as it did last time. Whether you order your food in Alaska or Arkansas, this is still the case - you always know exactly what you're going to get.

But their biggest innovation was the creation of true 'fast' food. The McDonald brothers were the first to apply first-order manufacturing and production line principles into a commercial kitchen to create a level of efficiency that simply no other restaurant could begin to compete with.

There's a great scene in 'The Founder', where they show how the McDonald brothers conceptualized the redesign of the kitchens for maximum efficiency. They chalked out the kitchen footprint on a tennis court, and gathered the employees to enact their roles in the kitchen.

They iteratively refined the layout until they came up with the perfect system - with minimal time in moving from process to process; eliminating double handling or backtracking; and ensuring that there were no employee crossovers or bottlenecks.

Their first attempt was rather incredible in comparison to the status quo at the time; but the concept has been further iterated and latest technology leveraged to continue their reign as pioneers of efficiency. Automation, pre-prepared and packaged ingredients, custom engineered catering equipment and top ergonomic and anthropologic commissioned research has continued to develop their process efficiency even more.

Although some of their solutions are indeed specific to the catering industry; there are certain principles which their kitchens are based off:

Standardization: McDonald's process is highly standardized, with each task and workflow carefully mapped out to ensure the most efficient use of time and resources.

Training and Process Protocols: Every employee is trained to perform tasks with maximum consistency.

Lean Operations: The elimination of waste and constant drive to streamline processes, with a robust supply-chain and pre-packaged products where appropriate. No movement is unnecessary, and no time is wasted.

Technology Integration: The use of technology to track, manage, and optimize performance (e.g., timers, sensors to assist in monitoring for quality control).

Speed Balanced with Quality Control: The balance between delivering a fast product without sacrificing quality.

These principles are largely transferrable to many applications; but for this example, I'm proposing a novel take on how to apply them in the context of operating theater design and fit-out.

The direct correlation: the McSurgical approach

Aiming to draw parallels as far as practicable with the above principles leads to create an initial brief for redesign concepts:

Standardized Surgical Processes: Just as McDonald’s has precise workflows for each menu item, hospitals can develop highly standardized procedures for operating theaters. It's accepted that some operations will have a degree of variability - as ultimately, every patient is different - but there are certainly many procedures that are similar enough to standardize for a large part. Surgical kits could be implemented that include only essential tools, pre-organized, sterilized and packaged for specific surgeries, reducing time spent searching and procuring equipment. Once spent, they can be repackaged into disposable containers for processing, incineration or sterilization by other staff.

Training and Protocols for Surgical Teams: Streamlining surgeon, nurse, and support staff training using clear protocols, much like McDonald's staff training on consistency and efficiency. Modular training programs have been utilized in many industries as a way of developing training for staff, and would equally work as well in this scenario - although it's noted that this is not a core component of this brief, so won't be focused on much further.

Lean Principles for Operating Theaters: Reducing unnecessary movement or steps by designing operating theaters with efficient layouts and tools that are always in the right place. The idea is to eliminate “waste,” such as unnecessary tool sterilization cycles, or inefficient use of resources.

Technology to Improve Workflow: Just as McDonald's uses point-of-sale systems to track orders, operating rooms can integrate software to track surgeries in real-time—monitoring instruments, team members, and progress. Robotics and automated solutions could serve to benefit this eventually, but there will be greater leverage from maximizing lean principles to start with - technology could deliver better efficiency, but it's implementation will come at a larger cost.

Theater Adaptations - some novel design attributes

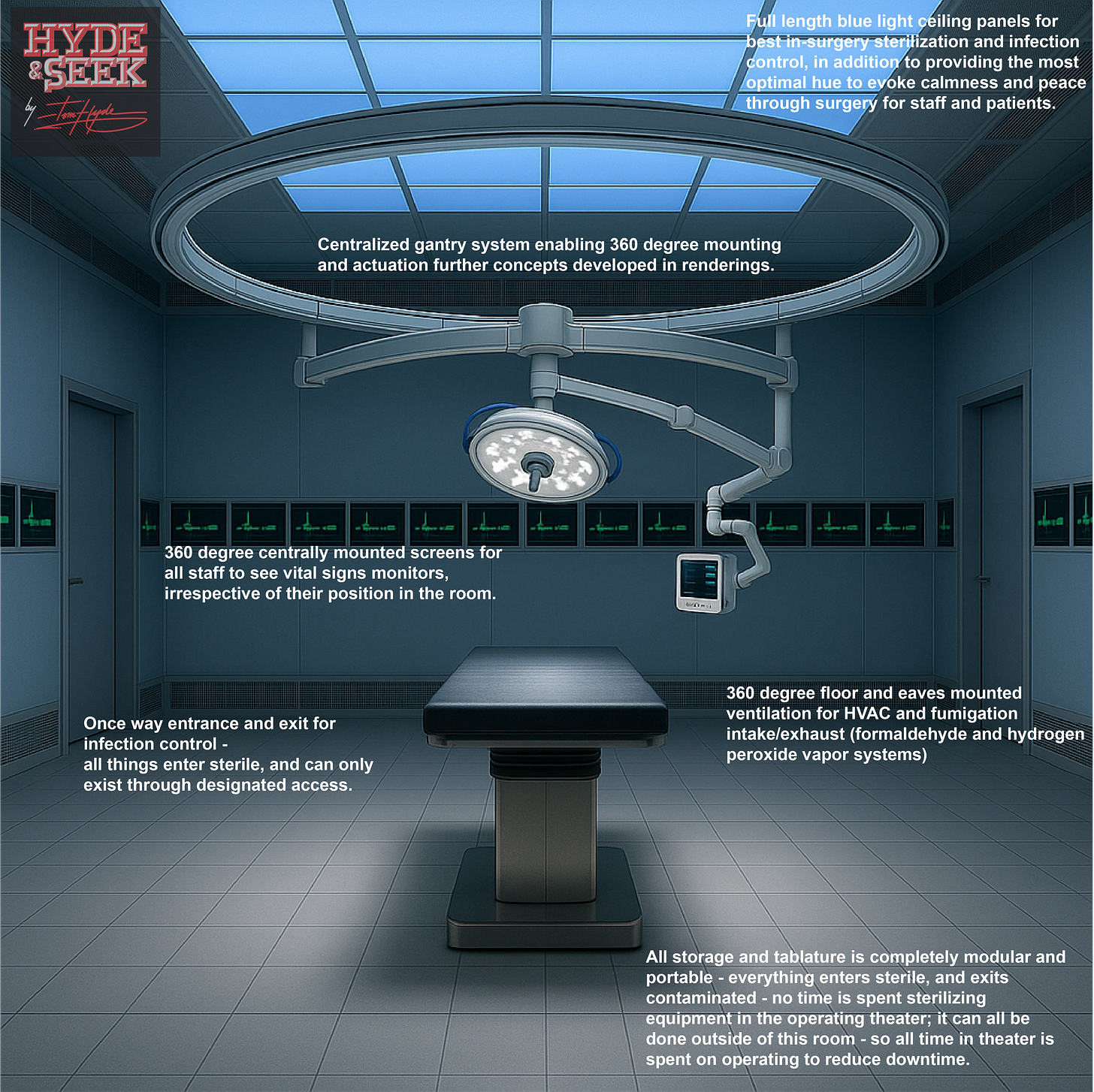

Centered and Modular - The Overhead Gantry Concept

Although ceiling-mounted fixtures are commonplace in operating theatres, there is a more universal solution capable of integrating increased modularity, ease of handling, and assistance for surgeons, staff, and patients to develop greater ergonomics and efficiency measures.

This will be similar to the solutions used in industrial manufacturing facilities for the use of overhead gantry structures which will feature rails capable of moving bearing-mounted fixtures.

Fixtures which are permanent and commonplace throughout all operations, such as:

Lighting

Diagnostics & Vital Signs Monitoring

Waste management (such as suction machines)

These can be mounted on the gantry system combined with articulating and actuating arms. These accessories can be rearranged in an infinite amount of configurations to suit the individual surgeon, the procedure, and patient welfare.

Additionally, certain fixtures could also be installed on the gantry system combined with motorised units to create an automated sweep function 360 degrees around the room; this will come in particularly useful for sterilization processes, which will be detailed in sections below.

Waste Disposal and Management

One efficiency measure that appears to be regularly overlooked within hospital environments, (admittedly, sometimes owing to the existing infrastructure and build design), is the waste disposal and management seen within operating theaters.

Which still can regularly rely on conventional lined bins where waste is segregated in the theatre itself before being bagged and taken elsewhere for processing.

Staff skilled in operational techniques are not best suited to carrying out basic sanitisation and waste segregation.

Therefore, similar to many other manufacturing processes, the waste disposal and management should be dealt with by a system that simply extracts all waste from the first instance where it can be separated and managed via automation screening or other manual separation by specialist hygiene professionals.

How this translates in reality is a centralised waste chute in the centre of the operating theatre. The all-waste can be quickly transferred into an underground conveyor system or chute system that will transfer the waste to a centralised processing location where instruments, metals, and other incinerable waste are collected via magnetization or detection. Other forms of hazardous waste and other medical waste can be dealt with by alternative means.

Fundamentally, this is ensuring that all time within the operating theatre is dedicated to practises pertaining to operating itself and no other ancillary operations such as cleaning or waste disposal. Are absorbing the time of the skilled members of staff.

This approach also ensures that there is minimum time and exposure to shared atmosphere between contaminated instruments or tissues and the operating theatre environment, ensuring that all potential contaminants are continuously being evacuated from the sterile environment. This practice will also assist in reducing sterilization cycle time between operations, potentially enabling operations to be carried out nearly back-to-back if required.

Sterilization and Infection Control - in-procedure and between procedures

It is recognised that no single fumigation or sterilization method is 100% effective. Therefore, a number of different approaches using the most common technologies would assist in serving the most efficient type of sterilization.

Certain fixtures could be installed on the Gantry system combined with motorised units to create an automated sweep function 360 degrees around the room, fixtures could even be multi-purpose - such as using the rear concave side of the surgical light to contain UV-C or Blue Light Panels. The concave outer will assist in serving to provide a greater spread and exposure to the light.

Floor and eaves vents are to integrate a full HVAC system, combined with a full fumigation system. This will enable the most effective longer cycle sterilization when time permits, but also features shorter cycle solutions between operations.

In practice, the most effective sterilization system will be an automated approach, using lighting panels and the HVAC/fumigation system in tandem:

Continuous sterilization where possible through the use of blue lighting panels overhead of surfaces, mounted as full ceiling tiles. There will also be Hydroxyl generators to run continuously throughout the room, in loop with continuous extraction and air treatment. Both processes are deemed to be safe amongst humans and equipment.

Between surgery - a 360 degree UV-C light sweep from a gantry mounted panel or fixture, which could be carried out in short cycles between surgeries. To improve efficiency even more, modular pre-sterilized carts with all equipment required are prepared in advance, and wheeled in as and when required.

Overnight and periods of dormancy - Hydrogen Peroxide Vapor and/or Formaldehyde Fumigation - typically longer cycles, creating a more sterile environment, and unlike the lighting based sterilizers - is not limited to line of sight exposure.

Finally, consideration could be given to a one-way system for all staff and patients to take:

An entrance where all equipment and staff that enter through it must be of a sterile nature prior to entering the theatre, to ensure that the sterilisation status is maintained and contamination only occurs at minimal levels and when absolutely necessary.

An exit for the patient following surgery back onto the ward.

Additionally, an ancillary exit for all of the staff, trolleys, storage equipment, operating tables etc to exit through to go elsewhere for sterilization.

In order to maintain the efficiencies of the operating theatre, new sterile equipment is simply wheeled in as modular units through the first door.

Ergonomics and Anthropological Considerations

The most recent data on ergonomics and effects of colour on neuroscience indicate that hues of blues and greens assist in maintaining an environment of calm and peace. This is typically seen amongst many of the existing medical equipment, but the blue panel ceiling will assist in developing this further. As a result, walls can be kept white in colour, gaining illumination hues from the blue light panel ceiling.

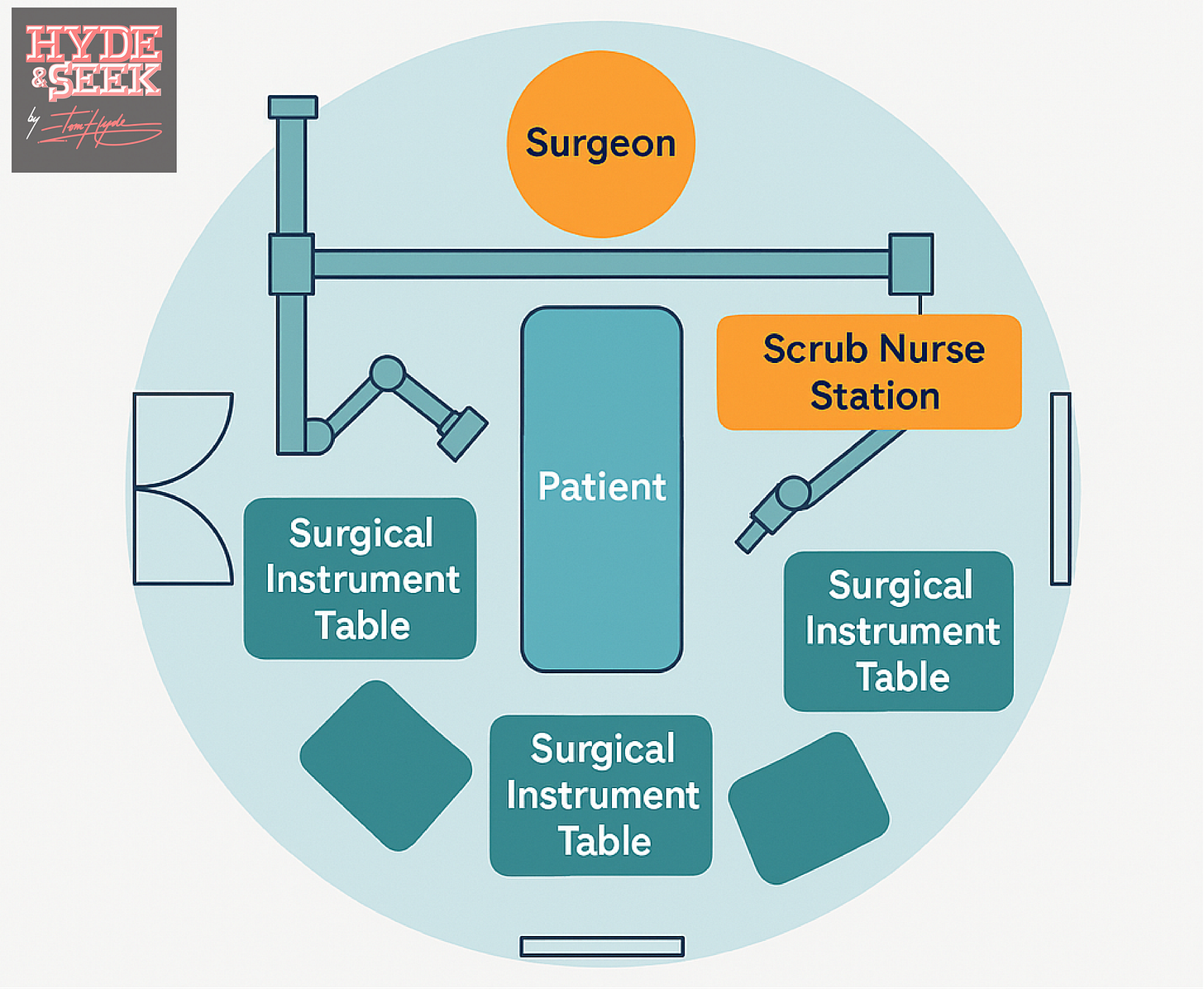

A direct crossover from the McDonald's model would suggest a redesign of the operating theatre with clear zoning and workflow paths to ensure that equipment, instruments, and staff are positioned to minimise any unnecessary movement.

Specifically, this will encompass a circular or U-shaped layout where the surgeon's main area, the scrub nurse station, and surgical assistance tools are within arm's reach for all parties, minimising the need for staff to move around the room during procedures. Finally, 360-degree screens mounted at eye level throughout the entire room will also assist in giving clear visual representation of vital signs throughout the entirety of the surgery to all parties.

In reality, this will transpire as effectively as smart operating theatre design, very much akin to smart home where lighting, temperature, and air circulation are controlled with a single interface.

There are plenty of other optimisations that could inevitably assist in refining any of these ideas further. The implementation of AI and other technological advancements will assist in improving efficiency to an even larger degree. However, in the interests of maintaining some brevity for this discussion, those concepts can be explored later in other publications.

It does serve an interesting concept however - often seeking inspiration internally to a problem simply results in an echo chamber; whereas looking to other industries as to how they overcame their challenges can often serve as a better starting point.

TH

You may also find these of interest: