Foam Sweet Foam: Why porous ceramic walls are the breath of fresh air data centers need

The common ground between a cactus, a camel and a pine cone could serve as groundbreaking - integrating phase-change materials into a ceramic foam pre-fabricated wall panel - for free, passive cooling

When we're designing things to fit into our modern environment, we often seem to overlook the obvious sources of inspiration, often hiding in plain sight. For many applications, teh best solutions for withstanding environmental considerations should probably begin with an animal or plant that has survived within it for several thousand millennia, long before we started to reinvent a solution to an existing problem.

We're all familiar by this point with the challenge of heat within data centers - how to manage it, dissipate it, use it, and even extinguish it. Most solutions are active, and usually require extensive HVAC or liquid cooling systems, requiring ludicrous amounts of energy.

There's a passive approach though, and conceptually it exists in cacti, camels and pine cones. It's the concept of dynamic heat regulation - and how these organisms use their cellular structures to open and close pores to control transpiration based on their temperature exposure.

Is there a way that we could turn the skin of the data center - the walls of the building themselves - to become a passive cooling system.

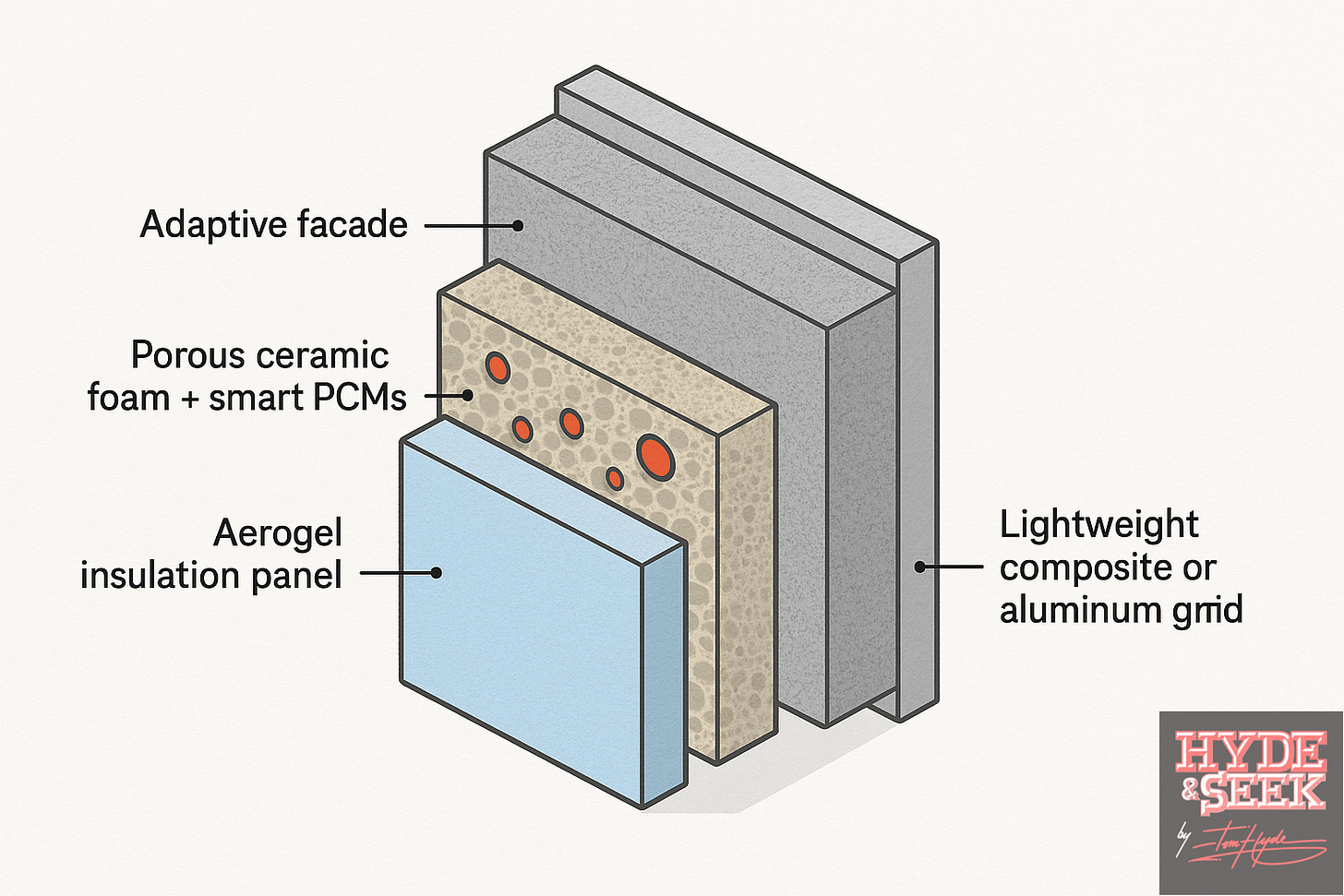

This novel concept explores the application of porous, ceramic foam walls with embedded smart phase-change materials (PCMs), hybridized with aerogel insulation and clad in adaptive facades - manufactured into prefabricated wall panels.

Together, this layered system could enable self-regulating, passive cooling for data centers—minimizing reliance on active HVAC systems, cutting energy costs, and redefining what's possible in data center design.

Reflecting on the Convection: Core Design Concept

1. Variable-Porosity Ceramic Foam

Engineered ceramic foams (such as silicon carbide or alumina) provide a structural and breathable base layer. These foams can be manufactured with graded porosity to promote natural convection airflow when internal temperatures rise, and restrict it when cooling is not needed.

By designing these foams with temperature-responsive porosity, it's possible to create structures that modulate airflow based on thermal gradients.

In cool conditions: Pores remain partially closed to conserve internal temperature.

In hot conditions: Pores open to allow convection and facilitate natural ventilation.

This mimics how certain desert plants or animal skins regulate heat exchange passively.

Some suggested materials options:

Alumina (Al₂O₃) - high thermal resistance, stable up to 1500°C - good for general use.

Silicon Carbide (SiC) - superior thermal conductivity, strong structural stability - best for high performance walls.

Zirconia (ZrO₂) - low thermal conductivity, high strength - useful in low-temperature environments

Recommendation: Silicon Carbide foam, due to its durability, heat conduction, and compatibility with phase-change material embedding. However, it will have to be combined with a hybridized construction technique and adaptive facades to respond to humidity within the outdoor environments.

2. Embedded Smart Phase-Change Materials (PCMs)

Phase-change materials embedded into the foam matrix absorb and release heat at specific thresholds, smoothing temperature spikes:

Daytime heat: PCM melts, absorbing excess heat without raising internal temperatures.

Nighttime cooling: PCM solidifies, releasing stored heat gently, extending the thermal stability window.

Standard PCMs buffer heat by melting and solidifying near target operating temperatures (e.g., 24–28°C). In this system, microencapsulated paraffin or salt hydrates are infused within the foam matrix.

The innovation lies in smart PCM integration:

Tiny temperature and state-of-phase sensors are embedded within the PCM capsules.

These provide real-time thermal profiling, enabling building automation systems to adapt in response.

Combined with IoT and AI systems, the walls become part of an intelligent feedback loop—predictively managing cooling loads.

Some suggested materials options:

Paraffin Wax; transitioning phase at around 25–30°C, with a latent heat of 200kJ/kg. Low cost, stable and easy integration; but not the most sustainable solution.

Salt Hydrates (e.g., CaCl₂·6H₂O); transitioning phase at around 29°C, with a latent heat of 190-220kJ/kg. Higher heat transfer but can be corrosive. I'd have concerns absout ambient gaseous salt ions reacting with metallic server hardware, which could increase corrosion rates.

Bio-based fatty acids; transitioning phase at around 20–28°C, with a latent heat of 180kJ/kg. This is the most sustainable solution, and is also biodegrable - but as a result, also relatively unstable.

Recommendation: Paraffin wax, for its safety, tunable temperature window, and ease of microencapsulation.

3. Aerogel Hybridization

Ceramic foam is structurally advantageous, but lacks the ultra-low thermal conductivity needed for complete insulation. To address this:

Silica-based aerogel blankets are proposed to be laminated behind the ceramic foam layer.

These aerogels have thermal conductivities as low as 0.015 W/m·K—lower than any other solid material.

They serve as a thermal break, keeping exterior heat from penetrating while allowing the foam-PCM layer to handle transient heat spikes.

4. Adaptive Facade Integration

The outer layer of the wall system can further enhance performance through adaptive facade technology. Options include:

Thermochromic coatings working via a color/pigment change with temperature to reflect more heat - enables passive solar control.

Phase-change shutters with louvers that open/close based on expansion of PCM wax - creating a mechanical-free control of airflow/light

Electrochromic glass qwith electrically controlled tinting glass; could easily integrate into other building automation.

Bio-mimetic skins (e.g., ETFE cushions with embedded actuators) with a dynamic envelope that expands/contracts with conditions - would enable an architectural flexibility and climate responsiveness.

Recommendation: Use thermochromic ceramic coatings on the exterior skin to modulate solar heat gain without moving parts, supplemented by mechanical-free PCM-based louvers for passive ventilation when required.

The Good, the Bad and the Ugly

✅ Passive, self-regulating cooling

✅ Low maintenance, with few to no moving parts

✅ IoT-enabled thermal intelligence, capable of real-time monitoring and dynamic adjustmebt

✅ Fire-resistant, chemically stable materials

✅ Reduces reliance on high-coefficient of performance HVAC systems

✅ Modular for retrofits and edge deployments

⚠️ Higher initial capital expenditure due to advanced materials; but arguably a quick return from savings in energy bills

⚠️ Moisture sensitivity of PCM and aerogels (requires robust sealing). If parrafin is not used as the PCM, some others would require encapsulation prior to embedding.

⚠️ Structural fragility of ceramic foam (requires composite frame reinforcement, but this could be fabricated from recyclable materials from conventional constructions.). Panels could not be utilized for load bearing

⚠️ Sensor calibration & long-term stability must be validated

⛔️ Parrafin PCMs arguably not the most sustainable material choice, but still the best for this application. Further PCMs could be developed for this application.

Manufacturing and Cost Profiling

Fabrication Process

Foam Casting: Silicon carbide foam panels formed via direct foaming or polymer sponge replication.

PCM Microencapsulation & Infusion: PCMs embedded through vacuum impregnation or mixed into slurry pre-firing.

Aerogel Layer Integration: Laminate aerogel insulation sheets to the back of foam panel.

Smart PCM Sensors: Add microthermal sensors at encapsulation or during post-processing.

Facade Layer Assembly: Add thermochromic ceramic coating or prefabricated dynamic cladding.

Final Encapsulation & Framing: Seal with breathable, waterproof membranes and mount into modular frames.

Indicative Bill of Materials [assuming a 1 m² Panel]:

Silicon Carbide Foam (10 cm) - $100

Microencapsulated PCM (2 kg) - $40

Smart Thermal Sensors (2–4 units) - $25

Aerogel Blanket (1 cm) - $50

Thermochromic Facade Coating - $20

Lightweight Frame (Al/Composite) - $20

Assembly + QA - $30

Total Bill of Materials assumes an approximate cost of around $285/m²

Advanced Design Techniques and Further Refinements

A slower manufacturing technique, but the benefits of an additive process - 3D-Printed Graded Porosity; to create customized porosity layers per panel section for directional airflow. Possible suitable for some sections of some walls where intake or exhaust flow is of more critical importance.

Utilising Finite Element Analysis, Digital Twins + Thermal Modeling to simulate and validate passive performance before deployment.

Turning Passive Walls into Active Participants

This concept is proposed to be a systematic-level rethink of the data center envelope. It's accepted that ceramic foam walls embedded with smart PCMs is not going to solely solve the cooling requirements for data centers, but could assist in being part of the solution for lower humidity environments.

As we approach the limits of active cooling and carbon budgets, concept materials like these offer a quiet revolution. Individually a small contributor, but collectively improving the performance and sustainability of our new essential infrastructure.

TH

You may also find these of interest: